ENERGY PRODUCTS

As GKD Energy, we continue to be an important solution partner in the energy sector with the products we design and produce specifically for the needs of our customers.

CRANES AND HEAVY CONSTRUCTION MACHINERY

→ Booms and turret made of high strength steel

→ Hydraulic lock safety on all cylinders.

→ Hydraulic operated horizontal & vertical outriggers.

→ Turret Rotation 360 °(± 180°)

→ Operating system for hydraulic pump in truck cabinet.

→ Operating system of the cranes on both side of the truck.

→ Suitable locked hook for the for the load capacity.

→ Articulation outrigger foot for any type of land.

→ Hydraulically operated rope pulley mechanism

→ 200kg capacity load steel basket attached to tip of boom

→ Manual pump stations for emergency cases.

→ Booms, chasis and turret made of high strength steel

→ Turret Rotation 360 °(± 180°) with planetary gearbox.

→ Safety locks in all cylinders.

→ ± 90° Basket rotation

→ Operating system for hydraulic pump in truck cabinet.

→ Operating system of the cranes on both side of the truck.

→ Articulation outrigger foot for any type of land.

→ LCD display screen for the weight of load and the length of vertical and horizantal boom tip.

→ Safety and balance at maximum load and lateral outrech

→ Glass made four sides and roof operator cabinet for operator comfort

→ Load capacity from 50tones upto 1200tones.

→ Unused and second hand cranes.

→ Hydrolic JimBoom (between 00-500)

→ Upto 250tones counter weight.

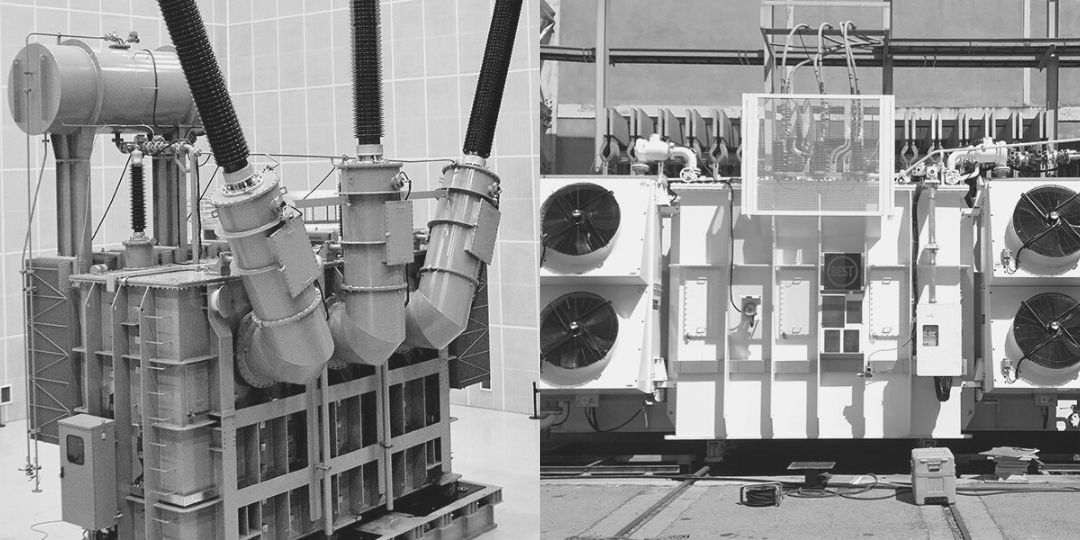

TRANSFORMERS

Power Transformers are electromechanical equipments and are designed and manufactured in accordance with the national and international standards (IEC, ANSI, BS, IEEE, etc.) according to customer requirements at 16000kVA and 72.5 kV voltage level and above. Power transformers have a wide range of technical characteristics such as power, voltage, regulation, impedance, losses, etc. GKD offers as a solution partner for its customers in every power and voltage range above 16MVA, in line with customer needs. Power transformers are used in electricity transmission lines, industrial plants, power generation centres and electrical internal needs.

Transformers that are designed to operate under extreme currents and reactive loads under special operating conditions for special purposes are called special type transformers. Special type transformers are classified as follows;

- Railway Transformers

- Auto Transformers

- Earthing Transformers

- Mobile Transformers

- Arc Furnace / Furnace Transformers

- Phase Shifting Transformers

- Serial Reactors

- Shunt Reactors

- Rectifiers

- Magnetically Controlled Shunt Reactor

Distribution Transformers are electromechanical equipment and are designed and manufactured in accordance with the national and international standards (IEC, ANSI, BS, IEEE, etc.) according to customer requirements up to 16000kVA and 36kV voltage level. Distribution transformers are used in urban distribution network, buildings and industrial plants.

It differs from oil type transformers according to the cooling method which is air instead of mineral oil. HV windings of transformers are produced with epoxy cast resin under vacuum. LV windings of the transformer can be produced by both cast resin and resin impregnated prepreg methods.

They are produced in natural air cooled (AN) or forced cooled (AF) options in the 25kVA – 25000kVA power range, up to 72,5kV voltage level. It can provide up to 40% power increase by using the cooling fans.

Temperature classes are variable according to the used insulation materials;

- F Class (155°C)

- H Class (180°C)

MEDIUM AND HIGH VOLTAGE ELECTRICAL EQUIPMENT

Metal Enclosed Switchgears are air-insulated switching, control and measuring equipment between 1 kV and 40.5 kV, manufactured in conformity with IEC 62271-200 with higher mechanical and electrical endurance to be used in indoor facilities providing continuous operations during the failures and maintenance.

Metal Enclosed Switchgears contain 3 segregated compartments.

→ Low Voltage Compartment

This compartment contains all secondary circuits for measurement, protection, control, monitoring, communication and other associated systems.

→ Bus Bar Compartment

This is the compartment where the energy is connected from the main busbar system to the switchgear or from the switchgear to the main busbar system. This compartment contains electrolytic copper busbars in compliance with the rated current and post insulators carrying the main busbars.

→ Switching Equipment and Cable Compartment

It is the compartment where the energy is connected to the substation, or the energy is received from the substation.

The components included in this compartment are given below.

- Switching equipments

- Current transformers

- Voltage transformers

- Surge arrestors

- Earthings

- Capacitive volatge divider

- Cable connection caplings

The switching component to be used in this compartment is selected according to the specifications of the circuit feeding or to be fed from the below alternatives or as a disconnector, breaker/contactor compound.

- SF6 Gas circuit breaker

- Vacuum circuit breaker

- SF6 Gas insulated Load Break Switch

- SF6 Gas Insulated Disconnector

- Rotary Disconnector

- Vacuum Contactor

-

- Main distribution boards

- AC Site distribution boards

- Compansation and motor control panels

- Syncronization, control and protection panels.

- Insulation power and DC distribution panels

- Transformer substations SCADA/HMI applications

- Unattended substation featured SCADA applications

- Dynamic electrical and communications visualization

- Reports, event and fault records

- Operator authorization and user operations records

- Distribution Management System specific software and functions

- Distributed Control System applications (DCS)

- Energy Management Systems(EMS)

- Automatic remote meter reading systems

- Load Management

- Short Term Load Forecasting

- Yoad Dispatch Control Center

- Fault Detection, Isolation and Restoration

Mobile substations are moving HV/MV distribution stations to be produced up to 250MVA power and 420kV voltage level, which are manufactured for use in HV/MV Distribution networks and High Voltage Transmission Grids according to the customer specifications and related standarts. According to the specifications and needs, it can be constructed on a trailer or wagon.

High Voltage Compartment: 52-420kV Disconnector, Circuit Breaker, Current Transformers, Voltage Transformers, Grounding Disconnector, Surge arresters, Post Insulator or High Voltage SF6 GAS Insulated System

Medium Voltage Compartment: 1-52kV Metal Compartment Switchgears, Metal Enclosed Switchgears or Gas Insulated Switchgears.

Transformer Compartment: 10.000 – 250.000kVA Power Transformer

Battery and Battery Charge Device Compartment: Battery, Battery Drawers and Charge Devices

Low Voltage Compartment: Low Voltage Indoor Distribution Panel / Compensation and Measurement Panel / DC Distribution Panel / Control and Command Panel / SCADA System

Operator Compartment / Generator Compartment

All other associated devices and compartments.

Basicly there are 4 type of generators and can be generate power from 1kVA to 3150kVA:

- Gasoline generators

- Diesel generators

- Bio diesel generators

- Natural gas and hydrogen generator.

A classification can be made based on the usage of generators that are portable or stationary.

In addition, generator types used for special purposes:

- Welding generators

- Portable lightning towers

- Marine generators

Circuit breakers are switching devices for cutting load current and short circuit currents in the medium / high voltage and medium / high current switching systems. It can open and close the circuit under load and especially in short-circuit, it can operate either manually or with automatic control.

The task of a breaker is to provide the flow of power from the circuit in the closed state and to prevent the flow of power in the open state. The most important task of the breaker is to open the circuit in case of short-circuit.

According to the place of use;

- Indoor type

- Outdoor type

→Usage for Outdoor type

- Dead-tank type circuit breakers

- Live tank type circuit breakers

Live Tank circuit breakers are cheaper than dead tank and require less space

→ type of arc quenching

- SF6 type circuit breakers, Sulphur hexafluoride gas

- Vacuum circuit breakers

Instrument transformers are high-accuracy class electrical devices used to isolate or transform voltage or current levels. The most common usage of instrument transformers is to metering from high voltage or high current circuits, safely isolating secondary control circuitry from the high voltages or currents. The primary winding of the transformer is connected to the high voltage or high current circuit, and the meter or relay is connected to the secondary circuit.

Instrument transformers are categorised in two type depending on insulation

→ Oil immersed type

- Outdoor type Current transformers

- Outdoor type Capacitive voltage transformers

- Outdoor type Inductive voltage transformers

→ Epoxy resin type

- Indoor type epoxy resin current and voltage transformers

- Outdoor type epoxy resin current and voltage transformers

According to the production technology, HV Current transformers can be produced in three different type;

- Bushing type oil immersed current transformers

- Head type oil immersed current transformers

- Tank type oil immersed current transformers

Disconnectors are basically safety devices, since their main goal is protecting the staff working in the substations, providing “VISUAL evidence” of circuit opening.

Type of Diconnectors

- Center break type disconenctors

- Pantograph type dşsconnectors

- Center break horizontal opening, Double break disconnectors

- Horizontal break knee Disconnectors

- Vertical break disconnectors

Other features;

- Disconnectors can be equipped with or without earthing switch

- Disconnectors can be operated motorized or manually

- Earthing switches can be operated motorized or manually

- Isolators can be porcelain or polymeric

- Single-phase or three phase